Products

Guide roller

ASide Guide Rollers are often used while training new belts, and in emergencies to keep the belt centered. Location of Guide Rollers on the carrying side should be about 10 feet back of the head pulley and then at intervals of 50 or more feet. Guide rollers in the return run of the belt should be located 10-12 feet ahead of the tail pulley so as to center the belt as it enters the tail pulley. Additional pairs may then be centered at 30-50 feet spaces

Wing Pulley

JMEP pulley manufactures a variety of using pulleys as well as maintaining a large inventory of the most popular sizes

- Crown Wing

- Mine Duty Using

- Lagged Mind Pulleys

- Spiral Using Pulleys

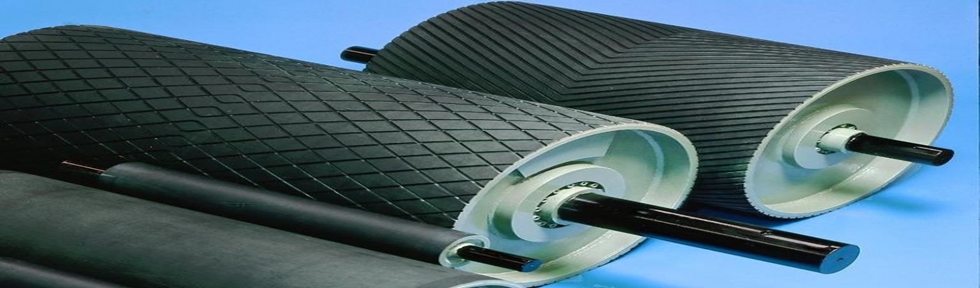

Drum Style

JMEP pulley manufactures a variety of drum pulleys as well as maintaining a large inventory of the most popular sizes.

- Crown drums

- Flat face drums

- Pipe pulleys

- Elevator drums

Bearings

JMEP maintains a complete line of mounted roller bearings at very competitive prices

- Pillow Blocks

- Flange Blocks

- Piloted Flage

Take ups

JMEP stock and supplies the most extensive line of roller bearing take-ups available

Elevator bucket

Rotary vane feeder

Our range of rotary vane feeder have been developed for maximum versatility in application. They are suitable for controlled discharging and feeding of powery or grandular materials from silos, hoppers, pneumatic conveying systems bag filter houses, or cyclones

Features of our rotary vane feeder includes:

- Easy access to all internal mechanical components

- Direct mounted drive without coupling

- Robust and compact design

- Space saving

- Various materials and treatments available according to product handled

Two way diverter

OV type diverters employ an axially mounted plate to control the flow of pneumatically transported materials. Flow may be diverted to one of two tubes, which intersect at a fixed angle. These diverters are available with options motorized and pneumatic application

Screens

Vibrating Screen

Vibrating screens are installed above bag filling machines, Roto packers and bulk loading stations. They offer an optimum safety against foreign bodies, material lumps and other oversize particles. Selection of mesh width, wire thickness and screen cloth material is done depending upon the individual requirement. With impeller type filling machines, screening is normally done at a mesh width of 5 mm square, and with air type filling machines and bulk loading plants, screening is normally done at a mesh width of 6.3-10 mm square.

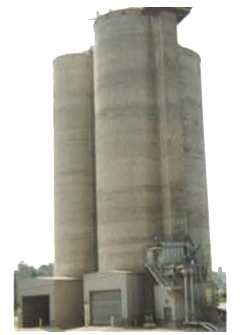

Storage Silo

We manufacture and supply Storage Silo equipments, which are as follows:

Silo (Storage & Blending)We are designer, manufacturer and supplier of silo feeding, aeration & extraction system of inverted cone, flat bottom and multi compartment silo designed for capacity ranging between 1,000 to 15,000 mtr for cement, ash & clinker. Wherever pulverized material like cement, clinker, ash are to be conveyed, blended, metered, dispatched silo pack is your preferred partner. We shall ensure the silo meets your all requirements. We have also supplying complete system for blending silos for cement industry for various capacities. We have developed a dependable blending system which ensures constant quality mixing of raw material which is one of the major requirements for optimized kiln operation. Silo pack has supplied steel fabricated silos for cement industry

Bag Discharge Conveyor

Bag Discharge Conveyor is designed for operation in-line with packing machine and bag conveying systems. The conveyor eliminates dust during untying, discharging, collapse, retying, and removal of bulk bags while increasing safety and promoting complete discharge of bag contents.

Slat conveyor

We offer Slat Conveyors that have one or more endless chains to prevent interlocking and overlapping spaced slats. The slats are made from either wood or metals. The slats are useful for conveying heavy loads of heated materials.

Belt feeder

Belt feeders consist of short belts operating over flat roll idlers with skirt plates to contain the material. Selected for smoothness of operation and uniformity of discharge, they are used below bins or hoppers to measure the flow of the material. They handle virtually all materials except those which are too hot, contain exceptionally large lumps or are very light and fluffy.

Turn table

We offer turn table which help to divert the material from same place without changing the direction of conveyor.

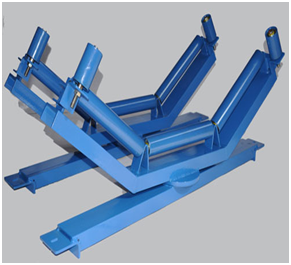

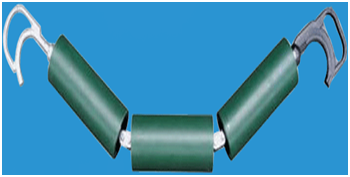

Trough training idler

Trough training idler is installed between the normal idlers to adjust the transverse displacement caused by unevenly loading , wet condition of bottom of belt side and bad training of belt when the carrying belt moves against the guide rollers on either side, the upper stand is swiveled to centre the belt. Then zigzag movement and abnormal damage of belt can be efficiently prevented

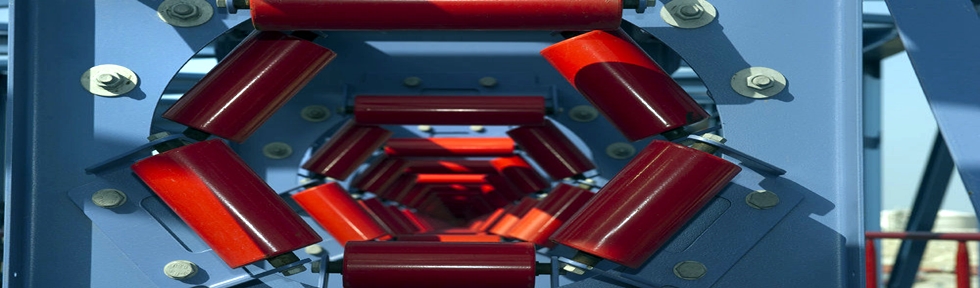

Three roll trough impact

Picking idler

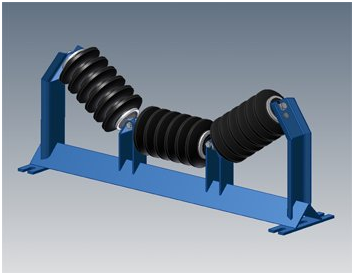

Rubber disc return idler

Fat carrying idler

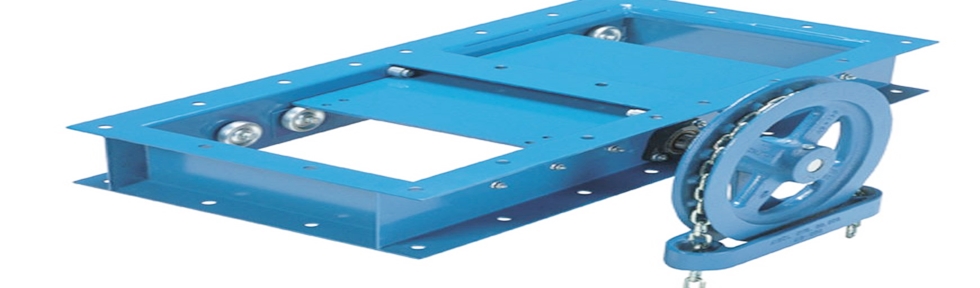

Rack and pinion gate

Flat Belt Conveyor

Set horizontally or at inclines up to 30° max, depending on product.

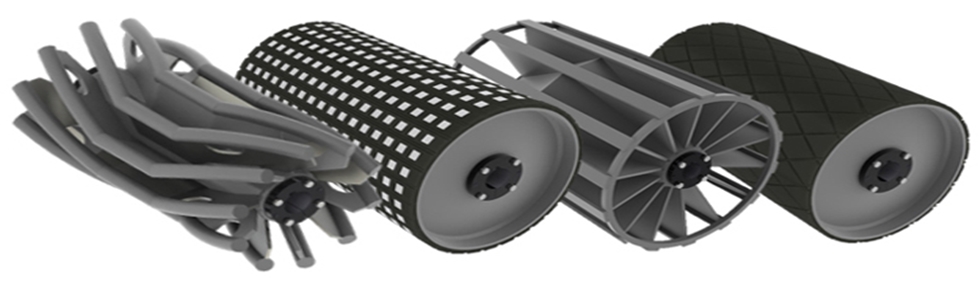

Belt Cleaner

CONVEYOR BELT LIFTER

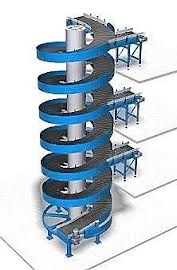

SPIRAL CONVEYOR

JMEP Spirals need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

JMEP Spiral conveyors are today being used in a rapidly growing number of small and large companies across a broad spectrum of industries. Our spirals effectively handle any conveyable load including bags, bundles, totes, trays, pales, cans, bottles, containers, wrapped and unwrapped items.

BAG TURNER

TUBE BELT CONVEYOR

Properties

Compact Design

Conveyor belt is formed into a tube conveyor belt

Protection of environment and material

Protection of the environment when hazardous

Contaminated, dusty or strong smelling materials are transported

Protection of material from rain, snow and wind

Application

Cement industry

Power station

Waste processing

Chemical industry

CONICAL ROLLER

TAPER ROLLER

V-RETRUN IDLER

GARLAND IDLER

CONCRETE BUCKET